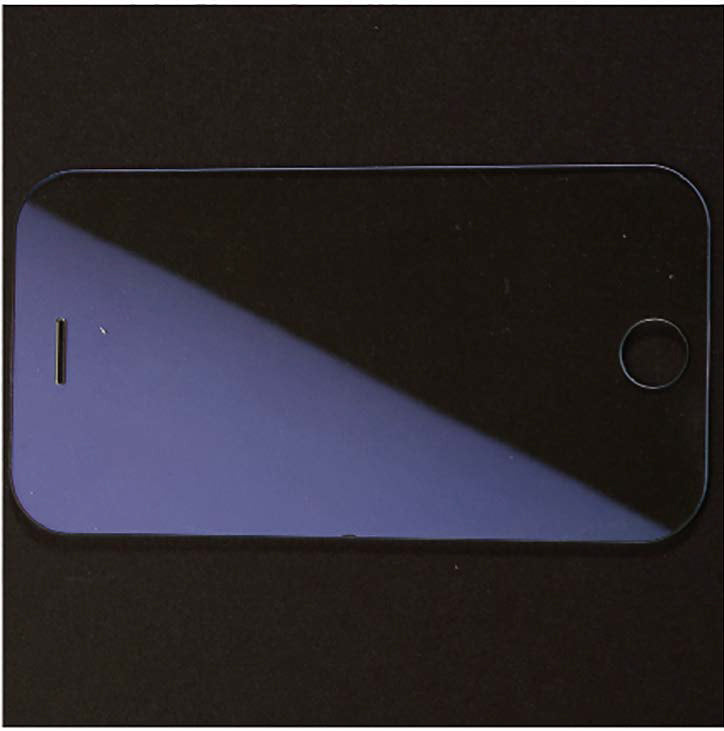

UV5, ultrasonic machining at your fingertips

Have you ever wondered how your phone's glass is made? At Ferrotall, we have the technology that makes it possible for your devices to have the highly durable glass that has become a global standard. Our representative Tongtai's VU-5 ultrasonic vertical machining center handles this task.

Among the various applications this machining center can perform are glass, sapphire, silicon carbide, quartz, ceramics, hardened steel, high-nickel alloys, and non-ferrous materials. Any material softer than the cutting tool can be machined using ultrasound. Ultrasonic rotary machining combines high-speed spindle rotation with high-frequency vertical vibration of the cutting tool. The diamond tool impacts the material at a high contact velocity, reducing cutting force and producing ultra-fine finishes, improving cutting efficiency by 3 to 5 times compared to conventional machining.

The VU-5 is a compact, precision machine that will exceed the demands of any manufacturer with high-precision machining needs. Its compact design requires very little space, while preheat time is minimal, and it will deliver more parts per hour than the competition. The machine is a fixed column/traveling table design. It features a Meehanite cast iron frame and roller-type linear guides for increased rigidity and faster, more accurate movement. The 25 mm (1 ″) ball screws are Class 3 with a double-nut pre-drawn design that allows a standard rapid traverse rate of 48 meters per minute in all axes with 1.2G acceleration. ultrasonic vertical machining center.

The ABS (Absolute Pulse Coder) servo system does not require absolute zero. The machine can be started at any time from any position, saving non-productive time. A chip sweeping system, fitted as standard, provides efficient chip removal.

The VU-5 is equipped with a 30-position, dual-arm, random-action tool changer. The dual-arm tool changer offers high-speed tool changeover, changing tools in just 0.8 seconds and 1.3 seconds from chip to chip. The 3 HP, 24,000 RPM direct-drive spindle comes standard with a Big Plus 30 (BBT-30) double-contact taper. Additionally, the machine features through-the-tool coolant preparation and a coolant-free spindle head.

For ultrasonic operation, the VU-5 comes standard with a system for automatically finding the optimal frequency and locking via M codes. The automatic tuning range is 15 to 45 kHz. The amplitude range is 1 to 10 microns. The machine also comes with a wide range of features as standard accessories for successful ultrasonic machining and a long machine life.

The 3-axis machine is equipped with a Siemens 828D control with a 10.4" TFT display, ShopMill, and Advanced Surface. The 5-axis version is equipped with a Siemens 840D control with a 15" display, the Sinumerik Mdynamics Technology package for 5-axis milling, and ShopMill.

As an example of other functions of the Tongtai Machining Center, we leave you the machine machining the iWatch casing.