Cutting tool

Cutting tools

In machining processes or systems for parts, cutting tools are instruments designed to remove sections or parts of a material, through an action known as chip removal, exerted by the application of a set of forces and movements.

The purpose of these elements is focused on the transformation or modification of parts into a final product, which is produced according to very precise functional and design parameters, for use in specific areas or sectors, including even the industrial sector itself.

Milling holders and plates

Milling is a machining process that involves rotating a cutting tool over the surface of the workpiece. This process is performed using a machine tool called an industrial milling machine, and the rotating cutting tool or insert is commonly known as a milling cutter. Among the instruments of this type are the following:

- Front milling cutter: It has cutting edges on both sides and the tip and is used to create grooves, holes or smoothing.

- Planing plate: This is an instrument used at a shallow depth on an almost completely flat surface to create the desired completely flat and smooth finish.

- T-shape: It is a tool used to make grooves across the width of the piece.

- Fly wing: used to make triangular shapes or molds, horizontally, on the base piece.

- Saw blade: recreates very tight or narrow cuts or grooves, which is why it does not need to be used at high speeds.

- Biconical cutter: It also develops triangular shapes, but unlike the fly wing, its cuts are made in vertical movements.

- Module cutter: This is a tool used in gear cutting, which makes cuts to generate the gear teeth.

- Chamfering cutter: Used to reduce the points or edges of a rigid part, giving them a flat or blunt appearance, a process known as chamfering.

For their part, those pieces responsible for holding the rotating cutting tool are known as holders .

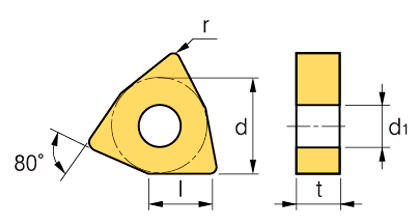

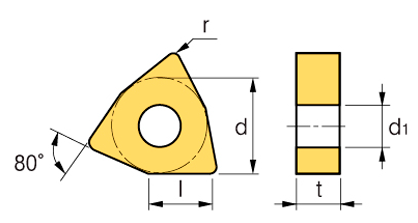

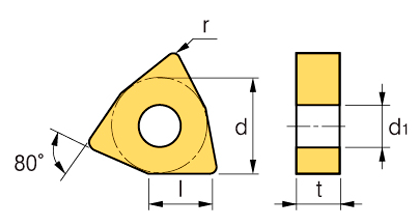

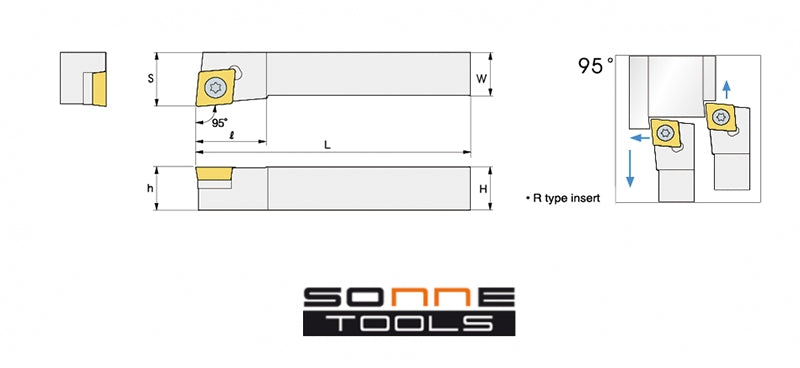

Turning inserts and holders

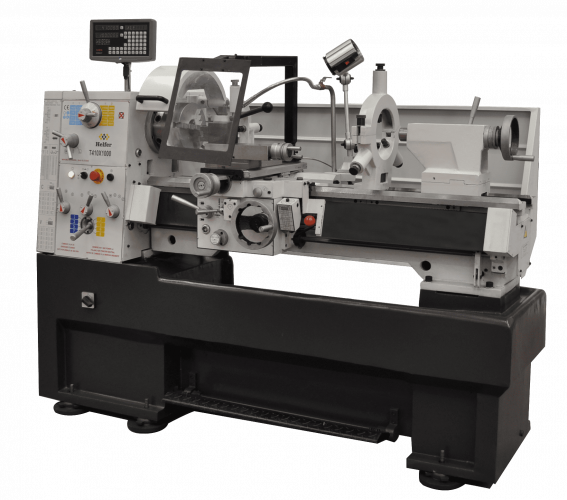

Turning is the machining process that involves applying a rotary motion to the base workpiece , not to the cutting tool. Turning elements are classified according to the technique used, including:

- Cylindrical: is an instrument used to reduce the diameter of a cylindrical base set to rotate on its own axis.

- Boring: the tool used in this technique is placed inside a circular bar or cylinder in order to enlarge the diameter of the hole.

- Exterior grooving: on a rotating base piece, this element allows grooves to be made on its surface to a desired width.

- Internal grooving: contrary to the previous case, the tool is placed inside the work material to make grooves on its internal part.

- Threading: These tools allow the production of threaded bars, such as screws and other similar instruments, which are very useful in all sectors.

- Cutting: The tool for this technique allows the machined material to be drilled, with the intention of generating a cut or separation of the piece.

In the similar case of the industrial milling machine, the turning bits are those units required to hold the different cutting tools.