Gags

Industrial clamps

An industrial vice is a tool used in industrial manufacturing and repair processes to friction-grip a workpiece. They typically feature two metal elements or a screw mechanism that attach to the workpiece to immobilize it. Clamping is achieved by continuously applying pressure to the workpiece, usually with the screw mechanism (or another type). This clamping is key to preventing parts from falling or shifting.

Most milling machines, drilling machines, and other machining machines and tools come standard with industrial clamps for this task. In many other cases, the clamp is already permanently attached to the workbench, the machine table, or other fixtures in the factory or workshop. Therefore, it is an indispensable part for this type of work.

Types of industrial clamps

There are different types of industrial vices. These vary depending on the intended use, their dimensions, jaw length, guides, and whether they have a fixed or mobile base. Any of the types shown here will hold the workpiece securely and stably so it cannot move or fall.

Industrial clamps according to their mode of operation

Depending on their operation mode, industrial clamps are divided into 3 different types: manual clamps, pneumatic clamps, and hydraulic clamps.

The last two are the most common ones found in any industrial process. Both are characterized by automating the closing and opening of the device. Furthermore, they are much easier to use and require less effort than a manual industrial clamp.

In pneumatic clamps, the clamping force is exerted by a pneumatic cylinder. This clamping is applied directly or with a lever system. They are therefore ideal for slightly more sensitive materials.

Industrial clamps according to their operation

Depending on their operating mode, there are two types of industrial clamps: fixed and rotating.

- Fixed-base jaws are the most common jaws on any machine. They also include jaws with tilting guides from 0 to 90 degrees.

- Swivel base clamps, on the other hand, have a fixed base attached to the bench and a mobile base located on the body of the vice.

The swivel base clamp is perfect for jobs requiring greater mobility and precision.

Industrial clamps according to use

Industrial clamps can also be divided according to their intended use. Here, we can distinguish between the classic screw clamp, the fixed or progressive feed clamp, and the spring-clamp clamp.

- The classic screw clamp is the most common and is usually made of wood or metal. They come in different sizes and require proper maintenance to provide optimal performance.

- The fixed or progressive feed jaw is ideal for most DIY jobs or those that are a little more delicate. Its main advantage is that the jaw wrench can be adjusted much more easily.

- Finally, the spring-loaded clamp is used to apply pressure to the bonding of small objects. It is easily adjusted and allows the operator to perform other tasks while the industrial clamp presses down on the workpiece.

What are industrial clamps used for and where?

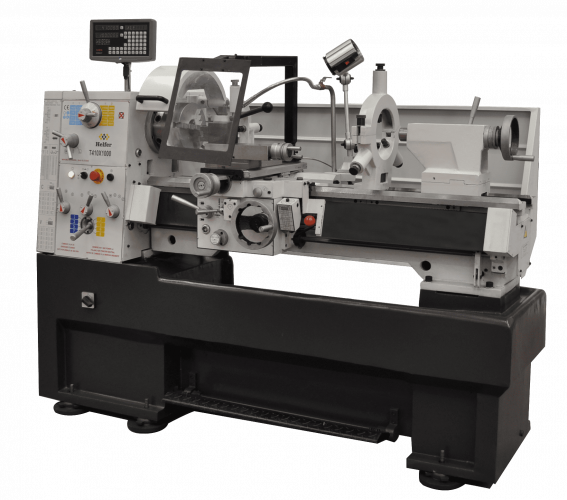

Industrial clamps are primarily used on milling machines, drilling machines, and other machining machines. Their main function is to secure the workpiece so that the operator can perform drilling or milling tasks more comfortably and accurately. They are a stable and safe solution that is essential.

Industrial clamps can also be used for other mechanical operations. The most common are sawing, drilling, filing, and marking. In all of these tasks, their function is also to firmly hold the workpiece to prevent any possible slippage.

They also have a spindle mechanism or crank that is responsible for manually opening or closing the jaw.

For any type of industrial vice, it's very important to know the maximum opening and jaw width. This way, the operator will know what type of workpieces it can hold. It's also helpful to know the load it can support, especially when machining heavy workpieces.

Industrial clamps are essential elements on any workbench or machining machine. Precision and accuracy in drilling, milling, and other tasks depend on the clamping of the workpiece.