Drills

Industrial drills

The industrial drill is a type of drill that offers a comfortable grip that allows for easy handling, making it the best tool for drilling large objects.

In this sense, it must be said that drills are not just tools, but also machines. Their most common use in workshops is to drill holes in some of the parts manufactured there. Unlike other industrial machines, drills are not complex to use.

They consist of two movements when used, and they are what allow industrial drills to drill through almost any workpiece. On the one hand, there is the rotational movement of the drill bit, and on the other, the forward or penetrating movement of the drill bit. This latter movement can be performed automatically or manually.

Types of industrial drills

An important point to know is that not all industrial drills are created equal. Some drills are milling drills, which allow for cutting in multiple directions in almost any material.

This is achieved because the drills and milling machines have a cast iron base, and the head height can be adjusted, so that the workpieces to be worked can be positioned without the risk of them being improperly held due to their size.

On the other hand, there are also portable industrial drills, among which the low-impact ones stand out. However, in terms of classification, only two different types of industrial drills are usually distinguished : the manual industrial drill and the vertical drill.

Both types of drills can be used for heavy-duty work, but they are designed to work with different types of materials, and in different positions. Below are the different types of vertical and manual drills that exist.

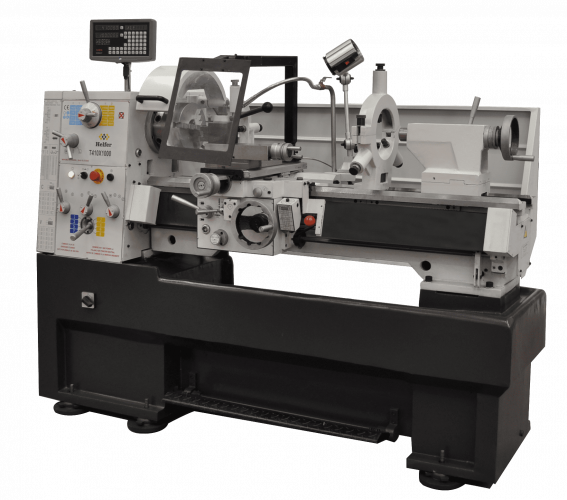

Column or vertical drill

Also known as a drill press, bench drill, or pedestal drill, this is a fixed industrial drill that can be bolted to the floor, workbench, table, or simply placed on a surface.

Generally, the smallest models of this type of drill feature a magnetic base, which holds the workpieces to be drilled. This type of drill consists of a table, a drilling head, a base, and a column. In most cases, the drill is powered by an induction motor.

In addition, the headstock has a series of cranks, which are turned by hand, and cause the chuck and spindle to move vertically, always remaining parallel to the axis of the column.

Radial arm drilling machine

This is an industrial drill designed to drill holes with a diameter ranging from 40 to 25 millimeters. They offer great precision and can be used to work with a wide variety of heavy materials.

It belongs to the vertical type of industrial drills, which is why it is especially effective for working with large parts.

Multi-spindle drill

This drill is designed for use in industrial production, as this is where it offers the greatest efficiency. It features a drilling head with a main spindle, which drives the subsequent spindles. It is capable of drilling multiple holes in a single process.

Industrial row and turret drill

This industrial drill can perform multiple processes on a single part. This means that reaming, drilling, and countersinking are all possible using this single tool.

The difference between the row and turret models is that the latter is controlled by a computer and has more than one head, allowing for the addition of different cutting tools, expanding the work possibilities.

CNC Drills

CNC drills are designed with more modern technology, as they feature a numerical control system that allows for automated operations. They are capable of operating at higher speeds than other types of industrial drills. They are also designed to offer precise precision in all operations.

In addition, they feature water cooling for the drill bits, which prevents overheating during the drilling process, ensuring safe handling of this tool. They also have a self-aligning drill bit system, can handle workpieces up to 100 millimeters thick, and have a five-meter-long work table.

Magnetic drill

This is a type of drill that offers great precision when working with metal structures, as it takes advantage of the benefits of magnetism to drill with greater accuracy.

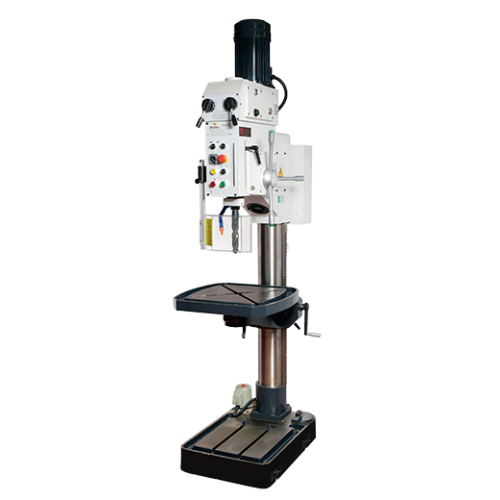

Column drill

It consists of a fixed drill installed on a stand. It offers great precision and is operated in a chain.