What is metalworking and what is it used for? Processes and uses

Metalworking processes

1. Foundry

Casting is one of the oldest processes in metalworking . It involves melting metal and pouring it into a mold, where it solidifies and takes on the desired shape. This process is used to manufacture parts with complex shapes that would be difficult or impossible to achieve using other methods. Casting is used in the production of engine blocks, machine components, and ornamental pieces.

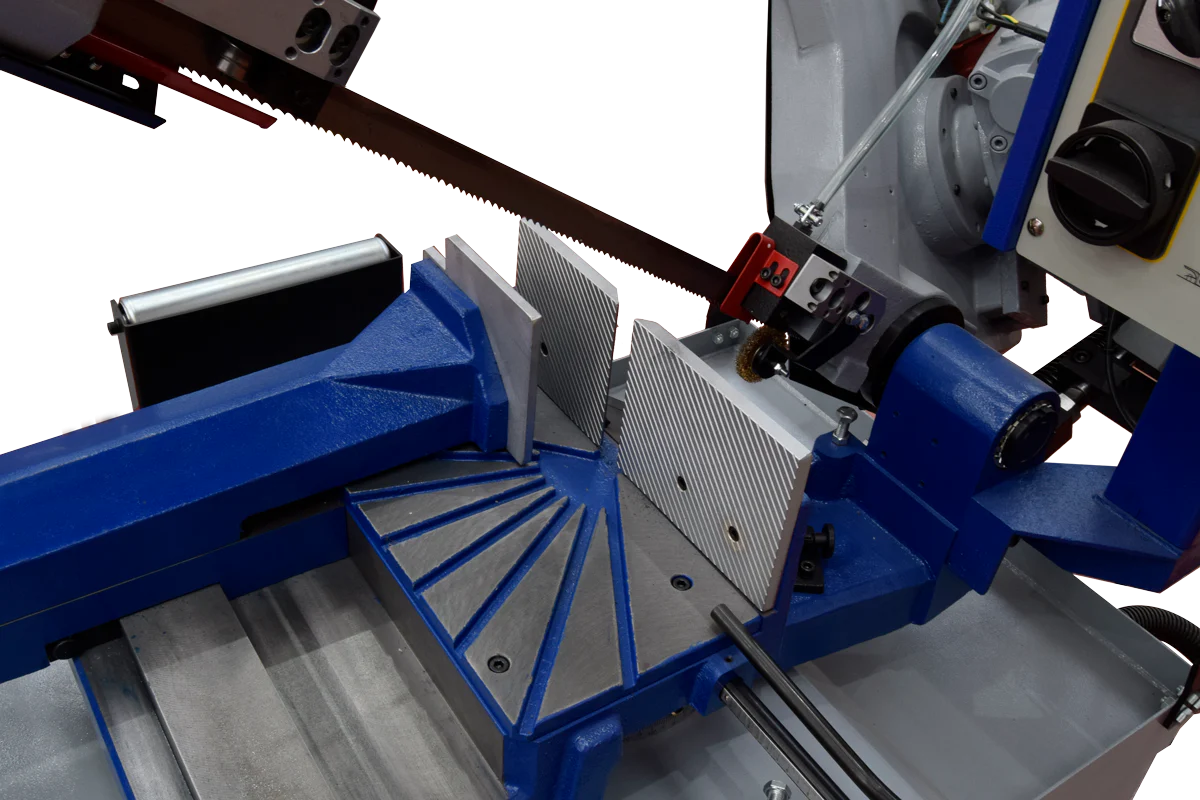

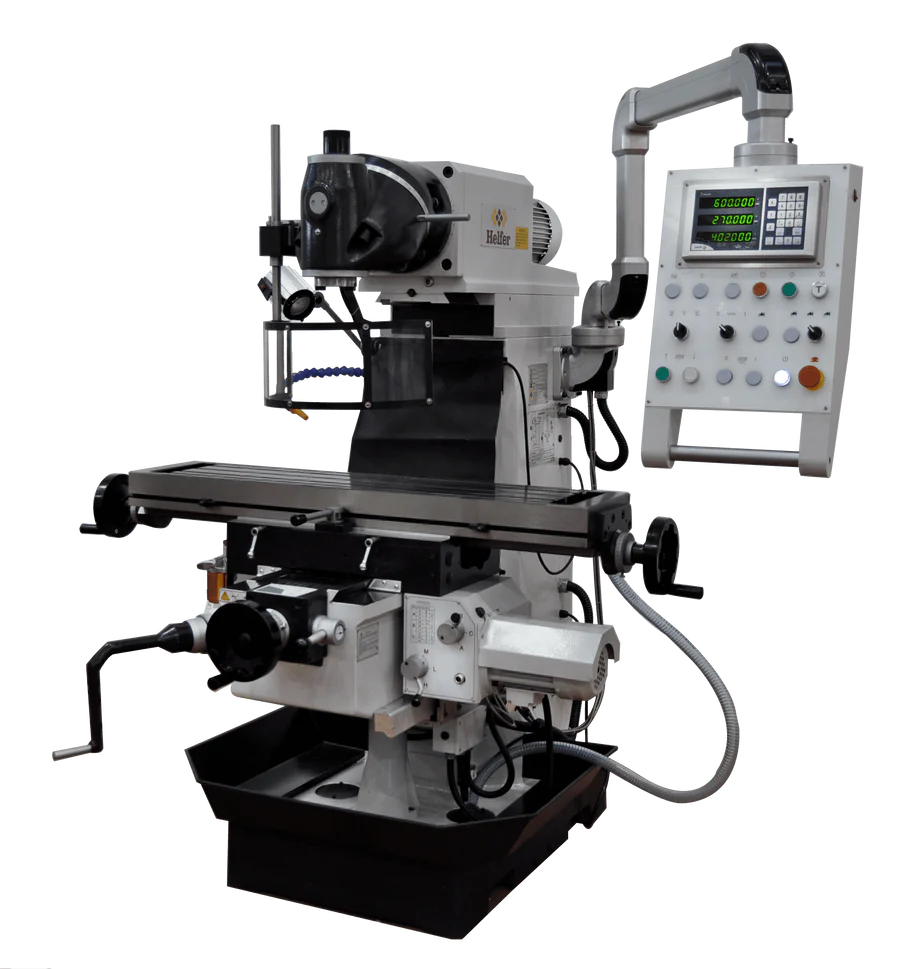

2. Machining

Machining involves removing material from a blank to achieve the desired shape and dimensions . This process is performed using cutting tools such as lathes, milling machines, drills, and grinders. Machining is crucial for the manufacture of precise components and is used in the creation of gears, shafts, and other mechanical elements. Helfer Industrial supplies these machining tools as experts and leading manufacturers nationally and internationally.

3. Welding

Welding is the process of joining two or more metal parts together by applying heat, pressure, or both. There are various types of welding, such as arc welding, MIG (Metal Inert Gas), and TIG (Tungsten Inert Gas). This process is essential in the manufacturing and repair of metal structures, pipes, and vehicle and aircraft components.

4. Formed

Forming is the process of shaping metals without adding or removing material, using plastic deformation . The most common forming methods include rolling, stamping, forging, and extrusion. These processes are essential for the production of sheets, profiles, tubes, and various structural parts.

5. Heat treatments

Heat treatments are used to modify the physical and mechanical properties of metals through the controlled application of heat and cooling . These processes include quenching, tempering, annealing, and normalizing. Heat treatments improve the strength, hardness, ductility, and other properties of metals, and are crucial in the production of tools, engine components, and parts subjected to high stress.

6. Coatings and finishes

Coatings and finishes are processes applied at the end of production to improve the appearance, corrosion resistance, and durability of metal parts . These include galvanizing, anodizing, painting, and powder coating. These treatments are essential for components exposed to harsh environments or requiring a specific aesthetic appearance.

Uses of metalworking

Metalworking is essential for the creation of a wide range of products and structures. The main uses of metalworking are:

- In the automotive industry , it is used to manufacture engines, bodies and transmission components.

- In construction , it is essential for the production of beams, columns and metal structures.

- In the aerospace sector , it is used in the creation of high-precision parts for airplanes and satellites.

In addition, metalworking is crucial in the energy industry , producing components for power plants, wind turbines, and oil and gas extraction equipment. In general manufacturing, it enables the production of machinery, tools, and equipment essential to other industries.