What is a milling machine?: types and operation

What is a milling machine?

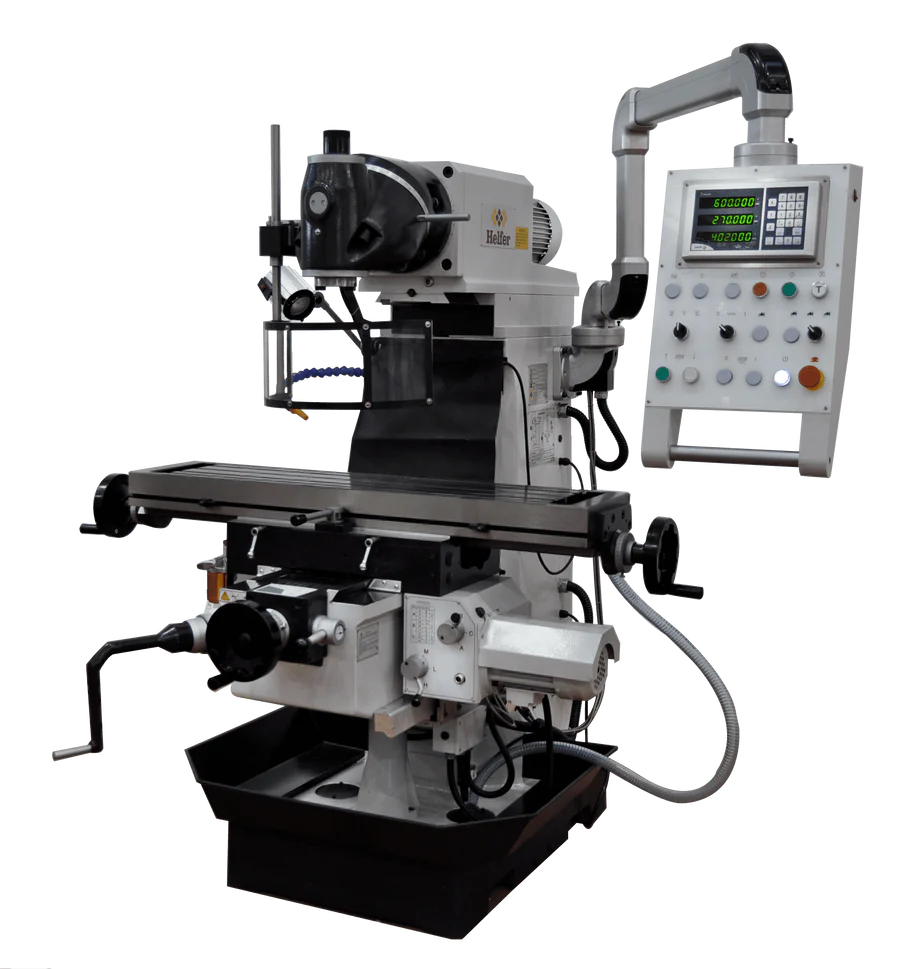

A milling machine is a fundamental machine tool in the manufacturing industry , used to machine various materials through the rotary motion of a cutting tool called a milling cutter. This equipment allows for precise machining of flat surfaces, curves, grooves, and complex shapes , and is essential for the creation of high-precision parts and components.

Features and functions of milling machines

Milling machines are known for their versatility and ability to produce fine, precise finishes. Some of their key features include:

- Robust structure: to withstand high-precision machining operations.

- Motion control: ability to control movements in multiple axes (X, Y, and Z).

- Variety of cutters: Various types of cutters for different applications, such as cylindrical cutters, disc cutters, angle cutters, among others.

Types of milling machines

Among conventional milling machines and other types, we can classify them into:

- Horizontal milling machine: The milling cutter is mounted on a horizontal axis, ideal for cutting flat surfaces and making grooves.

- Vertical milling machine: The milling cutter is mounted on a vertical spindle, providing flexibility in complex operations.

- CNC (Computer Numerical Control) Milling Machines : Offers automation and precision, allowing the programming of complex and repetitive operations with high accuracy.

Applications and uses of milling machines

Milling machines are used in a wide range of industries, including:

- Aeronautics: for the manufacture of structural components and precise parts.

- Automotive: in the production of engines, transmissions and mechanical components.

- Electronics: for the creation of casings and parts for electronic devices.

Advantages of using milling machines at Helfer Industrial

At Helfer Industrial, milling machines are essential for ensuring quality and precision in component manufacturing. Key benefits include:

- Precision and quality: production of parts with high dimensional accuracy.

- Versatility : Ability to work with different materials such as metal, plastic and wood.

- Efficiency: reduced production times thanks to the automation and programming of CNC milling machines.

Milling machines are essential tools in the industrial field, offering precision, versatility, and efficiency. At Helfer Industrial, we use high-quality milling machines to ensure excellence in the manufacturing of components and parts, adapting to the specific needs of each project.