Turning: What is it? Processes and advantages

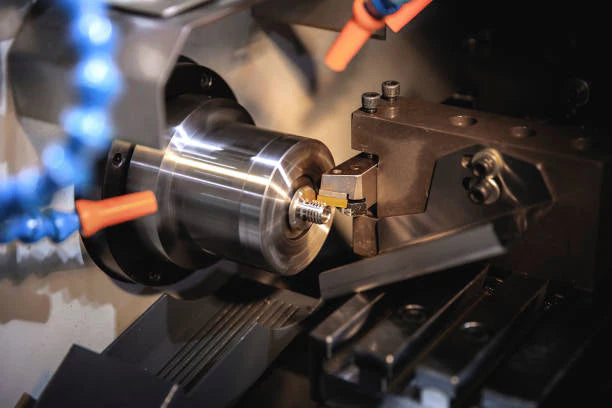

Turning is a fundamental process in the manufacturing of metal and other materials . It is performed on a machine tool called a lathe , which removes material from a rotating workpiece to give it the desired shape. This process is essential in the metalworking industry and in the manufacturing of precision components .

What is turning?

Turning is a machining technique in which a workpiece, usually cylindrical, is held in a lathe and rotated at high speed.

A cutting tool , fixed in a carriage, moves longitudinally and transversely against the surface of the rotating part, removing material in the form of chips to achieve the required shape and dimensions. This process can be performed in various configurations, such as external, internal, thread, and form turning.

TURNING PROCESSES

As for the main turning processes, we find:

1. External cylindrical turning

In this process, the cutting tool moves along the axis of the workpiece to reduce its outer diameter . It is one of the most common methods and is used to manufacture shafts, bars, and other cylindrical parts.

2. Internal turning (boring)

Boring is performed inside a hollow part to increase the diameter of an internal hole or cylinder . This process is crucial for creating precise fits in components that require an exact fit.

3. Thread turning

This process involves creating threads on the outer or inner surface of the workpiece. Threads can be of various types, such as metric, standard, or trapezoidal, and are essential for parts that require threaded assembly.

4. Shape turning

Form turning allows for the creation of specific contours and profiles on the workpiece. This process uses special cutting tools and motion patterns to produce complex and detailed shapes.

5. Facing

Facing is the process of cutting perpendicular to the workpiece's axis of rotation , used to obtain flat surfaces on the ends of the workpiece. It is essential for preparing parts for assembly or other machining operations.

ADVANTAGES OF TURNING

1. Accuracy and repeatability

Turning allows for high levels of precision and repeatability , which is crucial for the production of components that must meet tight tolerances. Modern computer numerical control ( CNC ) machines have further improved this capability, allowing for the manufacture of complex parts with high accuracy.

2. Versatility

Lathes are versatile tools that can handle a wide range of materials, including metals, plastics, and wood . They can also perform multiple machining operations with the proper setup, making them indispensable in workshops and production plants.

3. Efficiency

Turning is an efficient process that allows for rapid material removal and high-volume part production . Automation and CNC programming have further increased efficiency, reducing cycle time and increasing productivity.

4. Surface finish

Turning can produce high-quality surface finishes , which is important for components that require good appearance or minimal friction in mechanical applications. The right tools and techniques can achieve smooth, uniform surfaces.

5. Cost effective

For mass production of parts, turning is a cost-effective option . The high operating speed and potential for automation reduce labor costs and production time, resulting in an overall reduction in manufacturing costs.

Turning is a key process in the manufacturing of precision components, offering numerous advantages in terms of accuracy, versatility, efficiency, surface finish, and cost . Its application is fundamental in multiple industries, from automotive to aerospace, contributing significantly to the quality and functionality of final products.