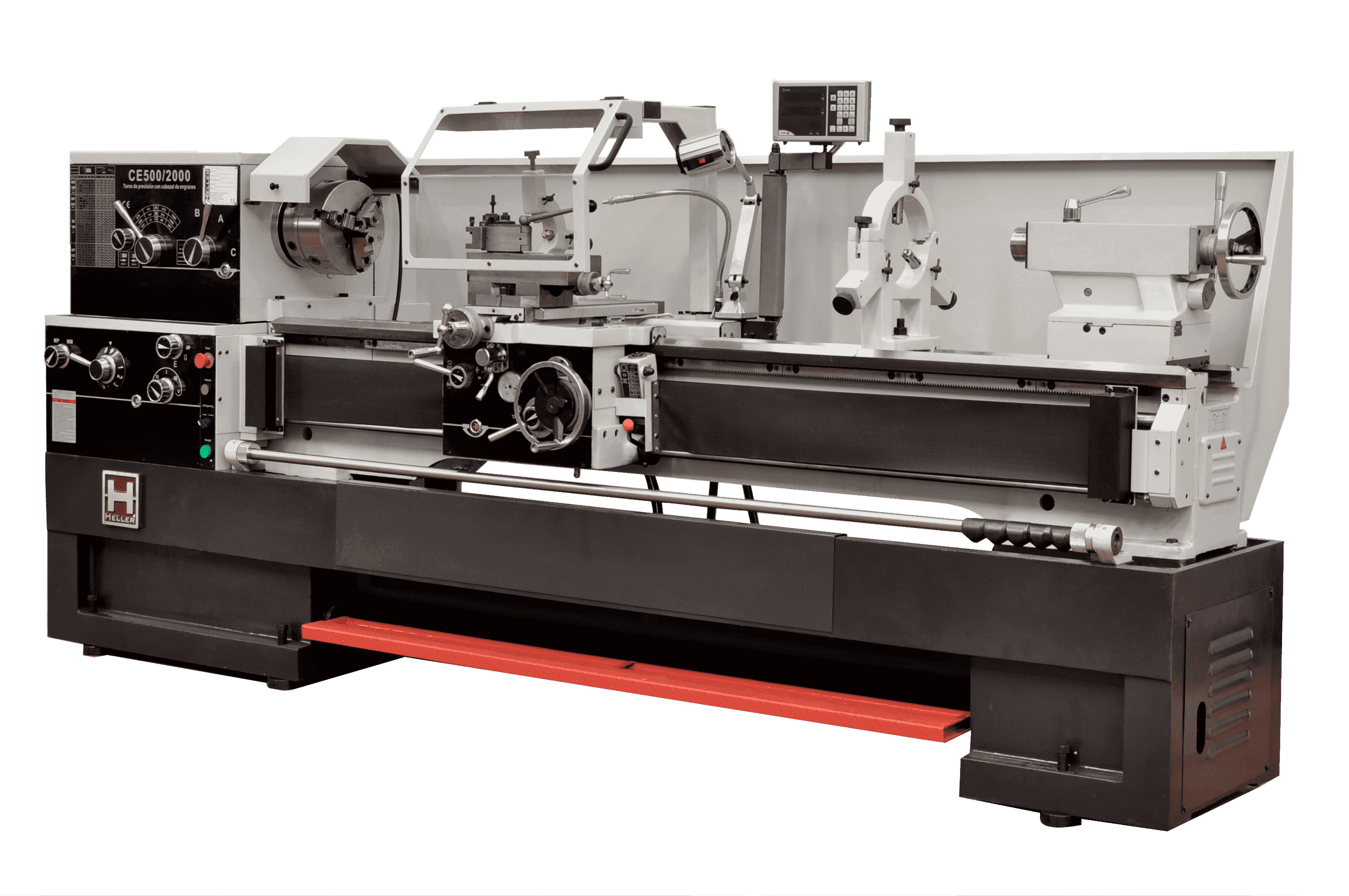

Maintenance of a parallel lathe

Preventive maintenance for industrial lathes is essential to ensure their efficiency and extend their useful life. Helfer Industrial offers a detailed guide for preventive maintenance for this equipment, highlighting the importance of regular inspections and adjustments .

Daily inspections

Every workday should begin with a visual inspection of the lathe. Check for visible damage, lubricant leaks, and that all moving parts are operating smoothly. It's crucial to clean chips and debris from the work area to prevent mechanical damage and ensure the lathe's accuracy.

Lubrication

A vital aspect of maintenance is proper lubrication. Be sure to apply specific lubricants to the lathe's friction points , following the manufacturer's recommendations. This includes spindles, guides, and gears. Proper lubrication reduces wear and prevents costly breakdowns.

Alignment and adjustments

Precise lathe alignment is critical for producing quality parts . Periodically check the alignment of the headstock and tailstock. Minor adjustments can make a big difference in the equipment's performance and accuracy. Use accurate measuring instruments to make these adjustments.

Weekly and monthly maintenance

In addition to daily inspections, more thorough checks should be performed weekly and monthly . Check the electrical system, cables, and connections for possible faults. Inspect and clean air filters and cooling systems to prevent overheating and ensure a safe working environment.

Replacement of worn parts

Identifying and replacing worn parts is a crucial preventative practice. Elements such as belts, bearings, and gears are subject to wear and must be replaced before they fail. Keeping a maintenance log helps you anticipate when these replacements are necessary.

Staff training

Ensuring that personnel are well-trained in lathe use and maintenance is just as important as the physical maintenance of the equipment. Helfer Industrial recommends ongoing training programs for personnel, ensuring everyone is familiar with best practices and safety procedures.

Implementing a rigorous preventive maintenance plan not only improves lathe efficiency but also reduces downtime and repair costs. Helfer Industrial is committed to offering solutions and advice to keep your equipment in optimal condition, prolonging its useful life and ensuring continuous, high-quality production.