Lathes

Industrial lathes

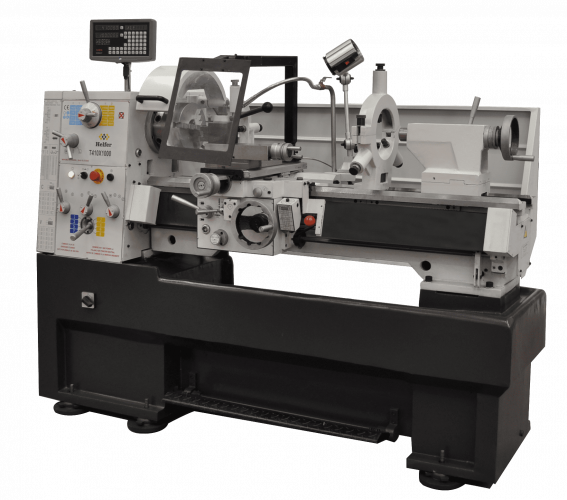

Due to their renowned versatility and performance, industrial lathes have important applications in the metalworking sector and facilitate large-scale part engineering, precise results, and worker safety.

In its definition, an industrial lathe is a type of machine tool capable of machining parts made of various materials, such as metal, wood, or plastic, by combining one or more turning techniques. The purpose of this operation is to convert the processed parts into functional products for any type of activity, including those related to the manufacturing sector itself.

Movements performed by an industrial lathe

Turning is a machining process that essentially involves removing part of a base part, using special blades, to give it a desired shape. Following numerous advances in the industry, this operation is becoming increasingly faster and safer thanks to industrial lathes.

To perform this task, the lathe uses three basic movements:

- Rotational movement: This is the main movement used by the system, and is carried out by the piece to be shaped, after being attached to the plate or support of the industrial lathe, which will make it rotate on its own axis.

- Feed movement: after the cutting tool is selected, it is propelled parallel to the blank to be machined until it is in the working position.

- Penetrating motion: This is the action generated by the blade on the surface of the base piece, in order to cut sections in a controlled manner, in accordance with the requirements of the final product.

The cutting tools used for machining the part allow for operations such as drilling, rolling, milling, cutting, threading, chamfering, boring, knurling, contouring, shaping, turning in conical or circular shapes, facing, roughing, or polishing, among other options that can be adjusted to almost any requirement.

Components of an industrial lathe

Currently, there are a variety of types of lathes used in industrial operations, including parallel lathes, copy lathes, turret lathes, automatic lathes, vertical lathes, and CNC lathes. Their specific characteristics respond to the needs of each production sector, primarily in relation to the number of parts to be machined, as well as the complexity and rigidity of the material being processed.

Even so, all industrial lathes, in general, are composed of similar components and accessories for their operation and the execution of the various machining movements. These components are briefly described below:

Main structure

| Bench | It is the base of the structure and primarily serves as a support for the rest of the elements. Its surface includes guides along which other units such as the headstock, tailstock, and portable carriage move. |

| Fixed head | It forms the main working axis. It is composed of the mechanisms that generate the machining movements and serve as the basis for the rotation of the workpiece. Its components include the motor, the spindle, the speed and feed selectors, among others. |

| Counterpoint | This component holds the material being treated at one point and places the other end firmly on a plate. Its features allow it to move along the bed. |

| Portable carts | They are made up of two elements: the main carriage, which will be responsible for generating the forward movement of the blade, moving along the bed; and the cross carriage, which will move perpendicular to the main carriage and the lathe axis to generate depth. |

| Rotating head | Also called a chuck, this is a unit whose function is to hold the workpiece or material to be processed. There are different types, such as four- or six-jaw chucks, universal chucks, and magnetic chucks, among others. |

Auxiliary equipment

| Clamping plates | These chucks hold the workpiece in the headstock or chuck. They can be universal jaw or soft jaw, the latter being more limited in use. There are also other variants, such as the drag chuck or independent jaw chuck, designed for materials that are not easily clamped. |

| Centers or points | These elements support the material at both ends, both in the rotating head and in the tailstock. |

| Drive pin | It is located in the headstock or chuck with the function of minimizing workpiece slippage and ensuring much more efficient turning. |

| Supports or lunettes | These components are divided into two types: fixed or movable. The former serve as a tailstock when, due to the characteristics of the workpiece, one cannot be used; and the latter are used to hold long workpieces near the machining point. |

| Tool turret | It is located on an auxiliary carriage and is capable of having multiple tools to be used in the same operation or machining process. |